Laser Cutting - Engraving

The devices that are used to cut, engrave and shape many materials by using laser beams are called laser cutting machines.

Laser printing is a colorless and permanent process created as a result of burning on the product with laser beam.

Laser engraving is a delicate wearing process performed with laser beam without applying too much power to the material surface.

With the machine used for many sectors and materials, it can process materials of almost any hardness level.

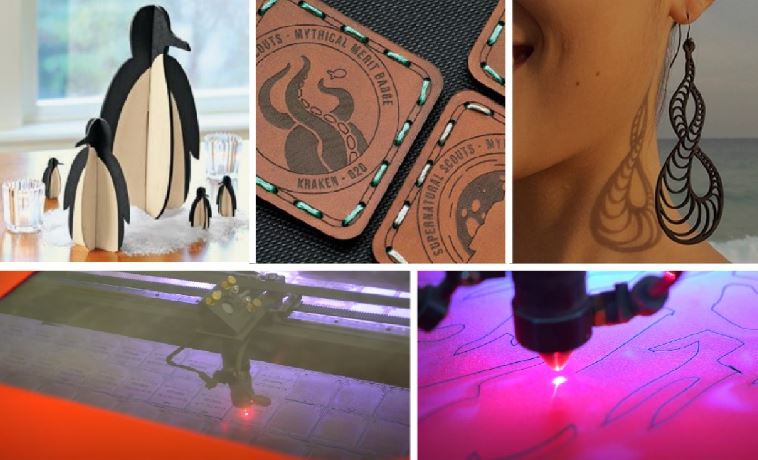

Today, cutting, engraving and marking of many creative products in sectors such as giftware, furniture, textile and decoration are performed with laser cutting machine.

Wall ornaments, embroidery on furniture edges, or marking on objects inside the house.

It can cut the most detailed works prepared on the computer with a laser cutting machine without error and without material pollution.

Personalized designs can be applied permanently on shoes, bags, purses, leather artificial leather, vinlex, pvc or metal lighter with a laser cutting engraving machine. Creative work can be done on the cell phone case or the phone itself, on the cover of a metal laptop. Laser cutting and laser engraving can be applied to glass glasses, pens, jewelery, and many other materials.

Thanks to the laser, perfect cuts without the risk of error can be obtained. In addition, many different designs can be created thanks to the scraping process. Scratching is the process of creating patterns by scraping a specified layer on the material to be processed. Products that will appeal to many sectors are produced by engraving with a laser cutting machine.

This device, which provides convenience in every sector, consists of five different parts.

– Laser Source

– Moving Engines

– Control card

– Machine Body

– Power Supply, Cooling and Vacuum Engine

Laser cutting machine is used on many materials. These materials consist of many other raw materials such as steel, plastic, wood, glass, plexi, paper, food, fabric and polyester. Manpower and manual operations can be performed easily with this device. Due to the structure and mechanics of the device, all operations such as cutting, scraping and burning are performed quickly and perfectly.

Laser, literally, is light amplification by the stimulated emission of radiation. The device supplies electricity to the laser source inside the glass or metal tube. By means of this electricity, the laser takes the form of a beam and this beam is transmitted to the area to be treated with the lens and mirror, so the material is cut or engraved as desired.

Laser sources in the form of metal tubes and glass tubes are used on different areas and materials. Metal products can be cut with “metal tube laser cutting machines”. Materials such as fabric, plastic, cardboard, wood and plexi can be cut with “glass tube laser machines”.

We process with our glass tube laser machine.

The use of a laser machine has many advantages over other methods.

These advantages can be listed as follows:

– Since no mold is used, the cost of the mold is eliminated.

– No deformation occurs on the material to be treated.

– Since it does not come into contact with the material during the cutting process, the material never bends, bends and stretches.

As a design, many pictures, patterns, logos and texts can be processed on the material.

– No roughness occurs on the surface during laser cutting or when the process is finished.

– It is low cost and allows very fast transaction

The products created in the laser machine with computer programs are used in many areas. With the laser machine, new products can be created from wood, plexi, plastic and more materials. In addition, patterns, texts and various embroidery can be made on existing products thanks to laser. The fact that unlimited design variety can be applied easily increases the demand of companies especially for laser cut products.

We can cut, engrave, and produce products and parts from many materials as follows.

Wood, acrylic sheet, aluminum, ABS, maple, aramid, acetal, artificial grass (astro turf), balsa wood, nitrile rubber (Buna-N), butyl tape acetate rubber, walnut, corian, pine, sycamore, burlap, perforated steel, delrin (POM polyoxymethylene), leather, ECH plastic rubber, diamond plate, diamond plate, EPDM rubber, EVA sponge, fiberglass, formex, formica, garolite, gore-tex, granite, rosewood, mild steel, carpet, HDPE, birch, linden wood, paper, capton, elm, carbon fiber, cardboard, poplar, beech, felt, chestnut, alder, cherry, composites, plywood, coroplast, fir, foam, foam core, fabric, quartz, ash, spruce, laminate, latex, LDPE, lexan, magnet, madrone, magnolia, cork, masonite, mahogany, MDF, marble, oak, nylon 6, neoprene, nitrile rubber, corrugated plastic, pre-galvanized steel, plastics, stainless steel, PETG, plexiglass, polyethylene, polycarbonate, polypropylene, polyester, P-tex, PVC sheet, redwood, cedar, cypress, hard wood, shim, rubber, silicone, silicone sponge, sorbothane, willow, sun ta, teflon, teak wood, titanium, canvas, UHMW, velcro, vinyl, viton, spring steel.